The future

of extraction

is solventless.

Growers work diligently to cultivate high-quality crops, then cannabis processors must pick their poison (sometimes literally) to extract. Producers of cannabis products had to make difficult trade-offs between cost, scale, safety, and their own values.

There’s a better way to extract cannabis.

We just invented it.

What is

Solventless

Extraction?

We’ve invented a new patented solventless extraction technology that is safer, cleaner, and faster than existing solutions, and it preserves the integrity and potency of the original plant.

Absolutely no additives.

We do not add solvents at any step in the process. That means no ethanol, no CO2, no hydrocarbons of any kind.

We don’t pollute the product. Or the planet.

What goes in..

is what comes out.

Efficient, clean and safe.

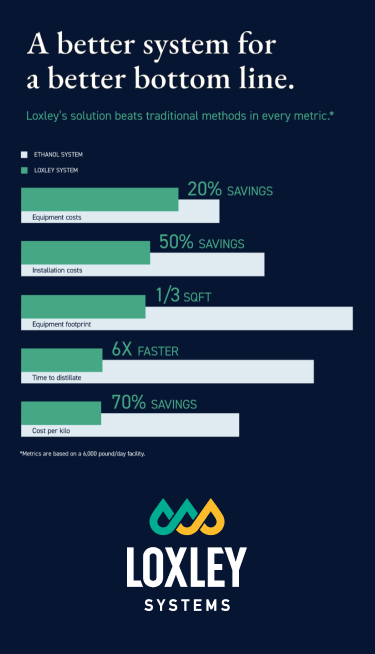

Solvent-based extraction solutions require expensive safety equipment and certifications. Loxley’s solventless extraction systems do not require Class 1 Div 1, contain no flammable or pressurized components, and need only a fraction of the staff.

The extracted oil is not crude - it’s a distillate, with over 80% primary cannabinoids and over 92% total cannabinoid content.

No waxes, no chlorophyll, no cleanup.

Safer for your staff, your facility, and the bottom line.

No Class 1 Div 1

is required

Loxley’s system is an all-in-one solution

With none of the extra processing required by other systems - like winterization, distillation, solvent recovery, or hazardous waste disposal - Loxley’s patented process produces a full-spectrum distillate in just one step, preserving the terpenes and cannabinoid profile and leaving only safe, compostable plant material behind.

Fast, cost-effective, and highly selective. Less work, more oil.

Plant to distillate

in 90 minutes.

Our Mission is to revolutionize the cannabis extraction process, making it more efficient, safe, and sustainable for people and the planet.

Raechel Sherwood, CEO

There are few plants as useful and versatile as cannabis, and we believe in its tremendous potential to positively impact the lives of human beings.

Steve Sherwood, CTO

Loxley's differentiator is our ability to take everything unnecessary out of the process, collapsing it into a single step. The plant product goes in, and the perfect distillate comes out.

The Innovators

- Kevin Sparks Ph.D.

- Greg Mehos Ph.D., P.E.

- Brian Van Blaricom M.E.

- Jonas Goslow, Tech & Mktg

F.A.Q.

Didn’t find your question below? Send us an email.

-

What is the Loxley System?

The Loxley System is a patented, all-in-one solution for extraction. Its continuous design allows for the production of full-spectrum distillate directly from plant material in under 90 minutes. No winterization, no chlorophyll, no cleanup.

-

What is full-spectrum distillate?

Full-spectrum distillate is the term we use to describe Loxley’s extracts. They are full-spectrum because they mirror the plant’s cannabinoid ratio. Unlike other extraction methods, however, Loxley’s process does not extract unwanted material. So the potency of our extracts are between 87-92% cannabinoids.

-

How does the Loxley System work?

Loxley’s System runs in two phases: terpene removal and cannabinoid extraction. The first phase is terpene removal, separating terpenes in 2-5 minutes. The speed of this step is crucial to preserving the terpene profile. The second phase is cannabinoid extraction. Through a proprietary blend of heat and gas, we are able to remove the cannabinoids in under 90 minutes. Our system then collects the terpenes and cannabinoid in separate vessels. Remediation or distillation systems can be installed in-line with our system to produce a fully formulated final product.

-

What size are Loxley’s Systems?

What size do you need? Loxley is able to scale anywhere from 750-100,000 pounds per day. All of our systems have a 4:1 turndown ratio, so they are designed to meet your needs today and into the future.

-

Does Loxley’s thermal process harm terpenes or cannabinoids?

No, Loxley’s system has been engineered to prevent degradation and oxidation. Terpenes are never exposed to oxygen and are removed very quickly and at very low temperatures. Cannabinoids are never exposed to temperatures greater than those used in a wiped film distillation system. We ensure that our system does not introduce oxygen at any point and we operate at unprecedented speed to ensure the safe collection of both terpenes and cannabinoids.

Get in touch:

Fill out the form below to ask us a question or to learn more about Loxley's extraction technology. We are also available by phone at 720-979-8487.